The idea to build a folding knife of this style has been around at least ten years. Back then I discovered a “Laguiole” knife kit on a rummage sale and was surprised how simple the mechanism works. My dad had been collecting these french knives as long as I can think, and so the idea was born to build a knife for him. The components of the kit were the perfect templates and so I bought the thing for a few bucks.

For whatever reason, I never really started with that project although I stumbled over this kit in my workshop every once in a while. Due to a pretty stressful job, I hardly had time to make knives anymore. When the Covid-pandemia hit the world and I suddenly had more time to waste in the evenings, I took up knifemaking and finally decided to try making this folder.

The first step, as always, was a sketch… or several sketches… the idea was to adapt the knife pattern a bit and shape the top of the spring as a trout – in the original french knives it is a fly or a bee (the debate among experts has been going on for decades). The only thing I was still not sure about was the material of the handles – I wanted it to be something calm and elegant, as e.g. ebony, so not to draw the attention away from the spring ornaments and the damascus blade. But I love walnut and desert ironwood aswell, and still considered them as alternatives…

blade

The blade was made from twisted damascus of two different sorts of steel (90MnCrV8 and 75Ni8). Both are excellent knife steels, one is alloyed with manganese, the other one with nickel, so that the pattern shows really nicely. The package was forged and welded in my coal forge, all by hand. Then it was twisted, forged flat and a blade ground from that blank.

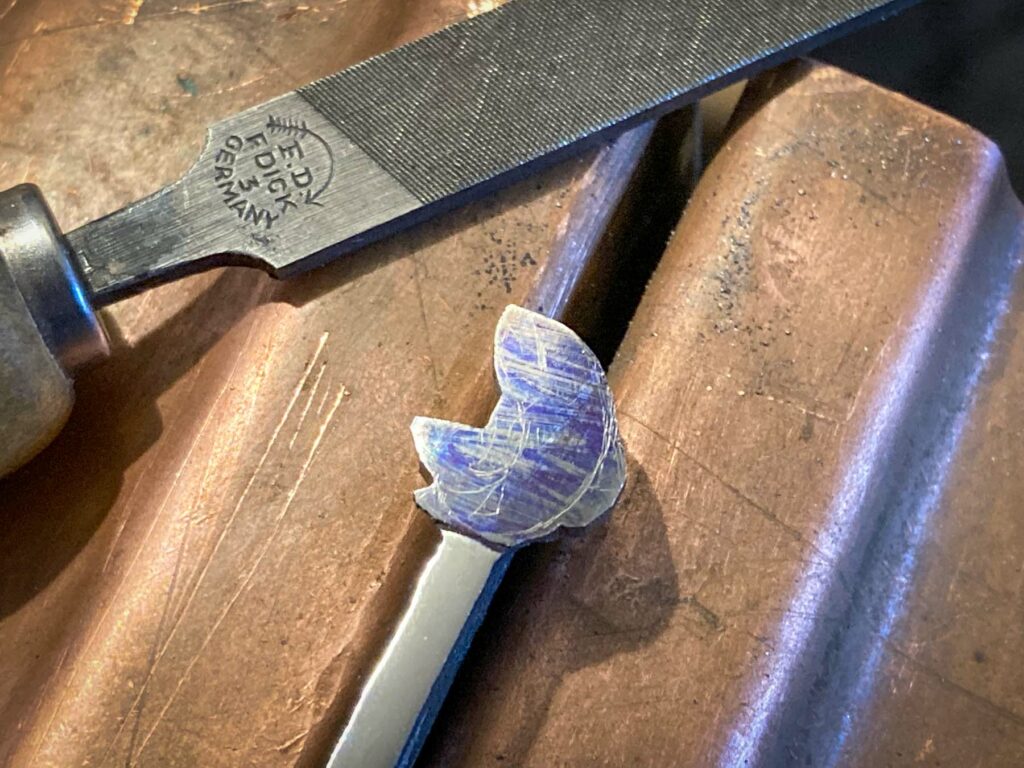

spring

To make the spring, several attempts had to be made. A piece of spring steel was forged broad on one end, so that there was enough room to shape a trout out of this part. The rest of the sping had to stay flat and parallel, which was quite a struggle. The shaping of the trout was done with files and chisels, and took several days as I had to proceed very slowly and the steel was quite tough.

handle

Both halves of the handle I filed from bronze (CuSn8). The originals are made from several sheets of metal, riveted together. I guess this is mostly due to economic considerations, but I wanted to make a single, exclusive knife, so I used solid bronze.

Concering the wood I chose ebony, which matches the bronze very well. The axis of the blade is made from 440B, a relatively corrosion-resistant and tough steel.

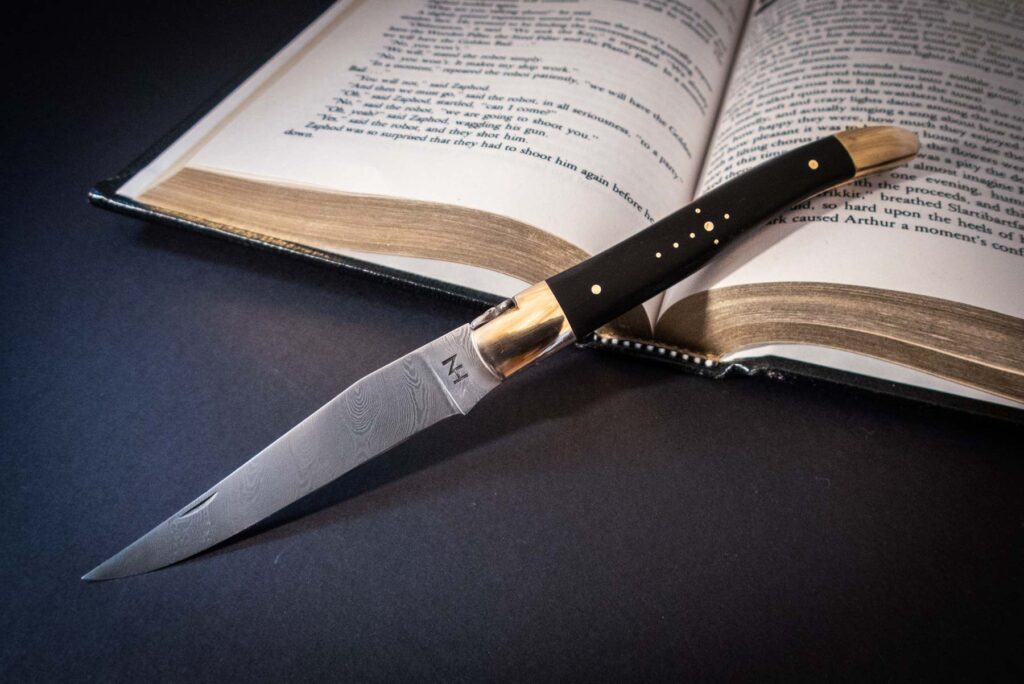

finished!

After many months of work, the knife was finally finished. It was the most time-consuming knife project I ever made… but one of the most interesting as well!